+91-8779193192

Boilers and Heat exchanger Overview, Advantages and Applications

Boilers and Heat exchanger Overview, Advantages and Applications

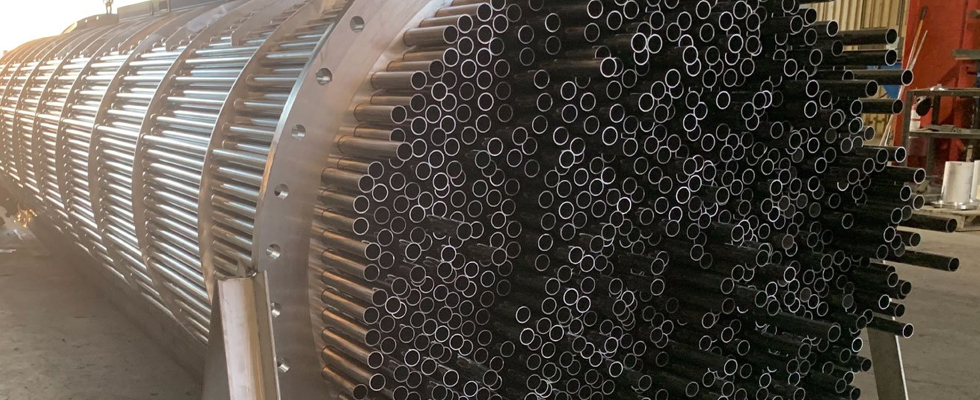

A Boiler is an enclosed vessel in which liquid or fluid, like water, is heated and vapor or steam is produced. This vaporized fluid or steam is supplied through pipes which is then used in various heating applications. Heat exchanger is used to transfer heat from one medium to another. Both Heating and Cooling Processes include heat exchanger in the process. Shell and tube heat exchangers, Double pipe heat exchangers, plate heat exchanger are some of the types of heat exchanger.

Boilers and heat exchangers tubes are available in Carbon Steel and Alloy Steel Materials. Both have their own advantages and applications.

Advantages of Carbon Steel Heat exchanger and Boilers Tubes:

Carbon Steel Heat exchanger Tubes deliver high performance even in elevated temperatures.

Carbon Steel Boilers Tubes are resistant to various corrosion and oxidation.

Carbon Steel Heat exchanger and Boilers Tubes offer good strength and moderate ductility, due to the presence of carbon content.

Carbon Steel heat exchanger and Boiler Tubes provide good creep strength and durability.

Advantages of Alloy Steel Heat Exchanger and Boilers Tubes:

Alloy Steel Heat Exchanger tubes offers resistance to stress, which makes it suitable for high working pressure.

Alloy Steel Boilers tubes have lower purchase and maintenance cost.

Alloy Steel Heat exchanger and Boilers tubes have high temperature withstanding capacity.

Alloy Steel Heat exchanger and Boilers tubes have high working pressure and low heat transfer rate.

Heat exchanger and Boilers tubes are used in many industries and applications like Air conditioners where heat is drawn from room and keeps it cool, evaporators, oil and gas industry, chemical processing, food processing, power generation, etc.